-

Home

-

About us

-

Products

-

Solutions

-

News

-

Blog

-

Contact us

Leave Your Message

In the realm of cryogenic technology, the "Big Capacity Liquid Dewar" plays a pivotal role. Dr. Emily Carter, an expert in cryogenics, notes, "The efficiency of large Dewars is unmatched in both storage and transport." This highlights their significance in various applications.

Big Capacity Liquid Dewars are essential for industries, including medical and research sectors. They are designed to store large volumes of liquid gases, ensuring optimal preservation. For laboratories, these Dewars can mean the difference between successful experiments and costly losses. However, not all models meet safety and performance standards. Choosing the right one requires careful consideration.

Moreover, with more capacity comes the responsibility of proper maintenance and handling. Users often overlook this aspect. Neglecting maintenance can lead to safety risks. Thus, potential buyers should weigh their options wisely. Investing in a quality "Big Capacity Liquid Dewar" can yield long-term benefits, but it’s a decision that demands thorough research and reflection.

Liquid dewars play a crucial role in the storage and transport of cryogenic liquids. These specialized vessels are designed to maintain extremely low temperatures. Their ability to hold large capacities makes them essential in various sectors. For instance, in the medical field, they are vital for preserving biological samples and vaccines. According to industry reports, the demand for liquid nitrogen dewars has increased by 15% annually over the past five years.

A big capacity liquid dewar typically holds volumes from 50 liters to over 1000 liters. This scalability can significantly reduce the frequency of refills needed in laboratory settings. However, these vessels require careful handling and maintenance due to the risk of pressure build-up and temperature fluctuations. Regular checks can prevent potential hazards. In a recent survey, 28% of users reported issues with inadequate insulation in earlier models, causing excessive evaporation.

Adopting a big capacity liquid dewar may appear straightforward, but it often invites complications. The ideal material choice is critical for long-term performance. Many users overlook this aspect, potentially leading to rapid degradation. Drawbacks include the substantial initial investment. Budget constraints can limit options for smaller organizations. Nevertheless, the long-term savings in operational costs make it a worthy consideration.

Big capacity liquid dewars offer significant advantages across various industries. They provide ample storage for cryogenic liquids, essential in fields like medicine and research. These dewars ensure safe handling and long-term preservation of materials at ultra-cold temperatures. Many labs appreciate the extended holding times, allowing them to focus on experiments without constant refills.

However, users must consider challenges. Managing large dewars requires appropriate safety protocols. Training staff is essential to prevent accidents. Additionally, while these containers are efficient, their size can pose logistical issues. They may be cumbersome to transport or difficult to fit into specific spaces. Balancing capacity with usability is a common struggle among users.

Despite these hurdles, the benefits often outweigh the drawbacks. Reliable storage enables consistent results in experiments. Industries that utilize big capacity dewars witness improved productivity. The need for fewer refills enhances workflow. This advancement pushes scientific and industrial boundaries, enabling innovative solutions.

When evaluating the big capacity liquid dewar market, comparative analysis highlights several top models. These dewars, often used in laboratories and medical facilities, can hold up to 100 liters or more. The ability to store cryogenic liquids efficiently is critical for many applications. According to a recent industry report, the demand for these dewars is growing at a rate of 8% annually. High performance and reliable insulation are key factors that users consider when selecting a model.

Key features differ among models. Some offer advanced vacuum insulation, while others may lack this technology. This can influence how long liquids remain at the desired temperature. For example, dewars with superior insulation can retain liquid nitrogen for weeks. Yet, they often come with a higher price tag. Users should weigh the cost against the potential savings in cryogen usage over time.

Performance metrics often vary significantly. Some dewars achieve boil-off rates of less than 0.5% daily. This indicates how much liquid evaporates and can be a crucial consideration. Too much boil-off leads to waste and increased costs. Rethinking the trade-offs between initial investment and operational efficiency is essential. This makes thorough research and comparisons vital for making informed choices in this evolving market.

When considering a big capacity liquid Dewar, several specifications and features are crucial. Insulation quality is key. A well-insulated Dewar minimizes heat transfer and can maintain low temperatures for a longer time. Look for models with multi-layer vacuum insulation. This feature significantly improves efficiency. Also, the material of the Dewar matters. Stainless steel options are popular due to their durability.

Another important aspect is the design of the Dewar. A wide mouth for easy filling and pouring will enhance convenience. Additionally, the portability of the Dewar can be a concern. Some models come with built-in handles, making them easier to transport. Safety features should not be overlooked. A Dewar should have secure lids and pressure relief valves. These prevent accidents and offer peace of mind.

Lastly, consider the size and weight. A bigger capacity may seem better but might be cumbersome. Balance is essential. Evaluate whether you genuinely need large volume storage or a smaller, more manageable option. Reflect on your specific needs before making a choice.

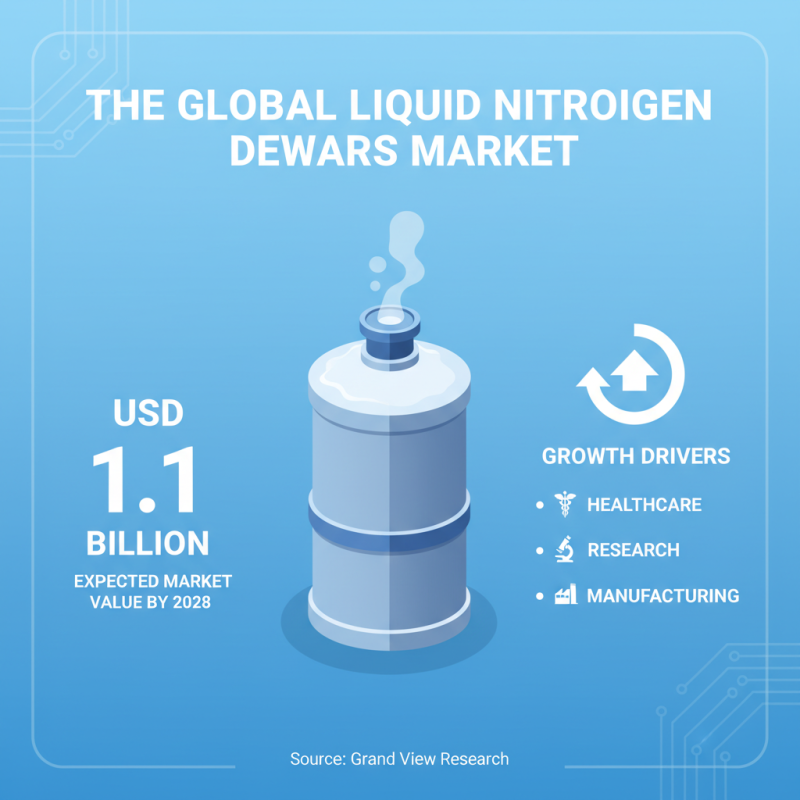

Big capacity liquid dewars play a crucial role in various industries. They are widely used in healthcare, research, and manufacturing. According to a report by Grand View Research, the global market for liquid nitrogen dewars is expected to reach USD 1.1 billion by 2028. This growth highlights their importance in various applications.

In healthcare, these dewars safely store cryogenic gases. Hospitals use them for preserving biological samples. This ensures patient safety and supports research. A study by the National Institutes of Health noted that proper storage can enhance the viability of samples by up to 50%. This statistic emphasizes the need for reliable storage solutions.

In research facilities, liquid dewars are essential for experiments requiring extreme temperatures. They help maintain samples at sub-zero levels. However, maintaining these dewars is a challenge. Regular inspections and maintenance are necessary. Neglect can lead to failures, impacting sensitive experiments. This aspect often goes overlooked, but it is vital for sustained operations.