-

Home

-

About us

-

Products

-

Solutions

-

News

-

Blog

-

Contact us

Leave Your Message

Choosing the right Cryogenic Refrigeration Systems can seem daunting. With various options available, it's crucial to understand the specific needs. Dr. Emily Thompson, a leading expert in cryogenics, once stated, "Selecting the proper system is not just a choice, it's a critical investment." Her insight emphasizes the importance of informed decision-making.

Several factors come into play when choosing a system. Efficiency, cost, and maintenance must be considered. Poor choices can lead to increased operational costs and inefficiencies. For instance, investing in outdated technology may result in higher energy consumption. It's not always easy to determine the best fit for a particular application.

Moreover, there’s always room for improvement. Evaluating the latest technological advancements can sometimes be overwhelming. Many businesses overlook necessary evaluations. In this complex landscape, taking time for reflection can lead to better decisions in cryogenic refrigeration.

Cryogenic refrigeration systems play a crucial role in various fields. These include medical, aerospace, and industrial applications. Understanding the principles behind cryogenic refrigeration can help in making informed choices. The fundamental principle is simple: cooling gases to liquefy them. This process often involves the use of liquid nitrogen or helium.

Applications can vary significantly. In medicine, cryogenic systems are essential for storing biological samples. They maintain low temperatures for long-term preservation. In the aerospace industry, these systems are used to test materials at extreme temperatures. However, selecting the right system requires careful consideration. It’s not just about efficiency; it’s also about capacity and cost.

Design flaws can lead to inefficiencies. An improperly sized unit may result in excessive energy consumption. This oversight can be costly. Additionally, maintenance requirements should be factored in. Regular checks are essential to ensure that the system operates optimally. Understanding these aspects can help in making the right choice.

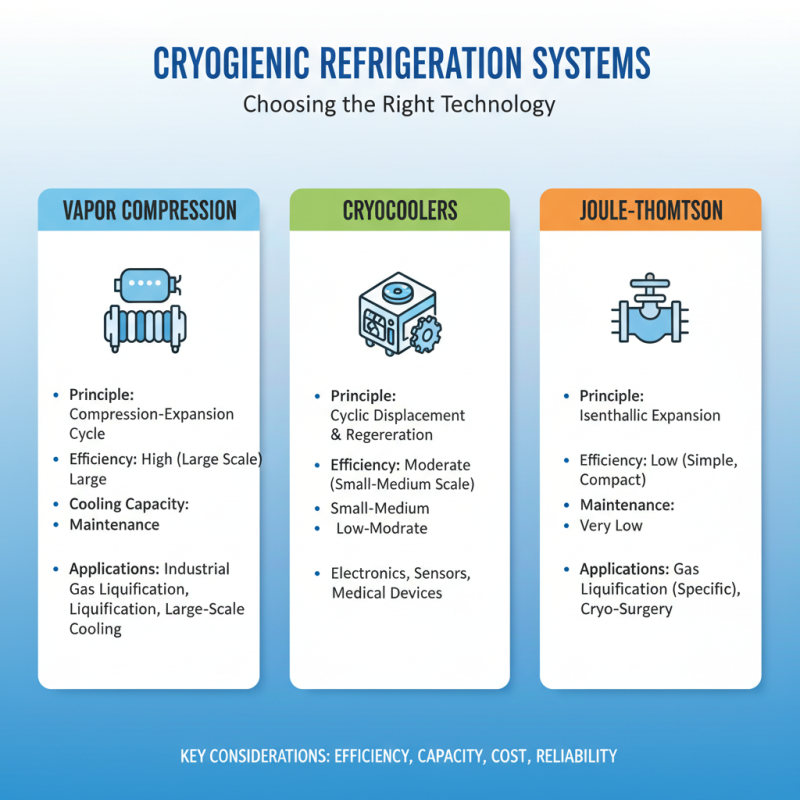

Choosing the right cryogenic refrigeration system can be challenging. There are various technologies available, each with unique benefits and drawbacks. Popular options include vapor compression, cryocoolers, and Joule-Thomson systems. Each system operates on different principles, impacting efficiency, cooling capacity, and maintenance.

Vapor compression systems are the most common. They provide a good balance between cost and performance. However, they may not always achieve extremely low temperatures. Cryocoolers, on the other hand, excel at reaching these lower ranges but can be expensive to run. Joule-Thomson systems are less common but can be efficient for specific applications.

**Tips:** Evaluate your cooling needs carefully. Consider factors such as temperature range and energy consumption. Maintenance requirements can vary significantly between systems. Always factor these into your decision-making.

Don't forget to assess the space available for installation. Some systems may require extensive infrastructure. Also, think about future scalability. You might need to adapt or upgrade your system over time. Reflect on how these factors play into your overall decision.

Choosing the right cryogenic refrigeration system hinges on understanding specific cooling capacity needs. Different applications demand various cooling levels. Medical facilities, for example, require precise temperature control for storing biological samples. It's crucial to have a system that can maintain consistent low temperatures. Any fluctuations can compromise the integrity of valuable materials.

When assessing your cooling capacity, consider the thermal load of your application. This means calculating the amount of heat generated by equipment and processes. Be specific: what are the maximum and minimum temperatures needed? These details impact the system's efficiency. Overestimating needs can lead to energy waste. Underestimating may result in equipment failure.

Don't overlook the insulation quality, either. Poor insulation can lead to heat gain, which complicates cooling. It’s a common oversight. Regular evaluations and adjustments may be necessary as demands change. Be willing to reflect on these dynamics. Balancing all these factors can be challenging, but it’s essential for optimal performance.

When considering cryogenic refrigeration systems, cost is a major factor. The installation and operational expenses can vary significantly. According to the Cryogenic Society, initial installation costs for these systems can range from $50,000 to $250,000. This wide range is influenced by system complexity, size, and required performance levels.

Operational costs are another key consideration. Data shows that energy consumption accounts for about 30% of operational expenses in cryogenic systems. Regular maintenance and servicing can also add up, averaging around $5,000 annually. These factors often lead to challenges in budgeting for cryogenic refrigeration.

**Tip:** Always gather multiple quotes for installation. Comparing prices can lead to significant savings.

System efficiency can greatly impact long-term costs. An efficient system reduces energy consumption, which can lower bills over time. However, many facilities overlook the importance of regular maintenance. Neglecting this can lead to greater expenses due to unexpected failures. Enhancing awareness regarding system performance is vital.

**Tip:** Track energy usage meticulously. This will help identify areas for improvement.

This chart illustrates the cost analysis of cryogenic refrigeration systems, comparing installation and operational expenses. The installation costs are significantly higher compared to ongoing operational expenses, highlighting the initial investment required for setting up these systems.

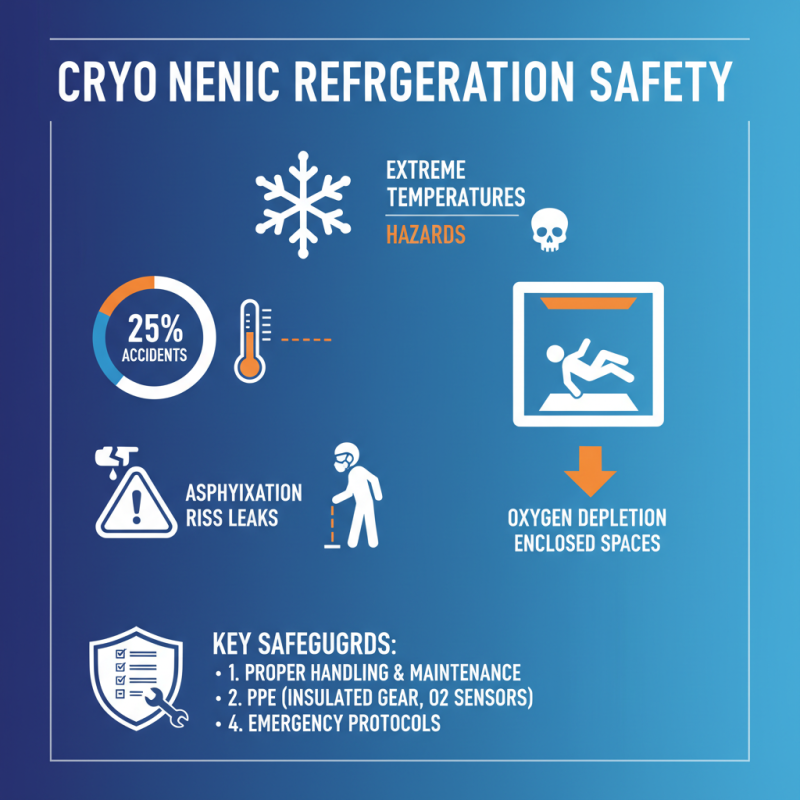

Operating cryogenic refrigeration systems requires meticulous attention to safety. The extreme temperatures involved can pose significant hazards to personnel. According to industry studies, improper handling and maintenance have led to 25% of reported accidents in this field. The potential for asphyxiation due to gas leaks is a serious concern. Oxygen levels can drop quickly in enclosed spaces, leading to dangerous situations.

Tip: Always monitor the oxygen levels in the work area. Use appropriate sensors to detect gas leaks. Training staff in emergency protocols is essential. A recent report indicates that well-trained personnel reduce incident rates by 40%.

Regular maintenance is crucial. Equipment must be checked for leaks, ice buildup, and operational efficacy. Neglecting these elements can lead to failures, risking both safety and efficiency. It’s often overlooked how equipment age significantly impacts reliability. Age-related issues can lead to catastrophic failures if not addressed timely.

Tip: Keep a log of maintenance schedules. Review equipment performance regularly. Reflection on past failures can guide better practices. It’s imperative to learn from mistakes to enhance future operations. The fine line between efficient operation and safety should never be blurred.