-

Home

-

About us

-

Products

-

Solutions

-

News

-

Blog

-

Contact us

Leave Your Message

In the realm of advanced engineering and technology, Cryogenic Refrigeration Systems stand out as extraordinary innovations that enable the manipulation and preservation of materials at ultra-low temperatures. These systems not only play a pivotal role in scientific research, such as in the fields of particle physics and biotechnology, but they also find applications in a myriad of industries, including space exploration and medical technology.

This comprehensive handbook serves as a tutorial designed to equip readers with the essential knowledge and skills needed to master the complexities of cryogenic refrigeration. From understanding the underlying thermodynamic principles to exploring the latest technological advancements and best practices, this guide aims to demystify the intricacies of cryogenic systems. Whether you are a seasoned engineer or a newcomer to the field, this resource will empower you to harness the full potential of Cryogenic Refrigeration Systems in your projects and endeavors.

Cryogenic refrigeration systems play a crucial role in numerous scientific and industrial applications, ranging from superconducting technologies to space exploration. Understanding the fundamentals of these systems is essential for engineers and technicians who work with temperatures below -150°C. At the core of cryogenic refrigeration is the principle of removing heat from a system, thereby achieving and maintaining extraordinarily low temperatures, which can be vital for processes like liquefying gases or preserving biological specimens.

Cryogenic refrigeration systems play a crucial role in numerous scientific and industrial applications, ranging from superconducting technologies to space exploration. Understanding the fundamentals of these systems is essential for engineers and technicians who work with temperatures below -150°C. At the core of cryogenic refrigeration is the principle of removing heat from a system, thereby achieving and maintaining extraordinarily low temperatures, which can be vital for processes like liquefying gases or preserving biological specimens.

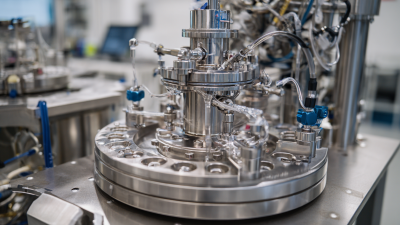

The basic components of a cryogenic refrigeration system include the compressor, heat exchangers, and expansion valves. These elements work in concert to transfer heat away from the specimen or environment being cooled. By employing various thermodynamic cycles, such as the Joule-Thomson effect or the Brayton cycle, these systems can achieve significant temperature reductions. A thorough grasp of these principles not only enhances operational efficiency but also ensures safety and reliability in applications where precision temperature control is paramount.

Understanding the interplay of these fundamental components is key to mastering cryogenic technology and harnessing its potential in innovative fields.

Cryogenic refrigeration systems play a crucial role in various industries, including medical, aerospace, and food preservation. Understanding the essential components of these systems and their specific functions is vital for effective operation and maintenance. Key components include compressors, condensers, and expansion valves, each contributing to the refrigeration cycle. Compressors increase the pressure of the refrigerant, while condensers facilitate the heat exchange process, converting gas to liquid. Expansion valves control the flow of the refrigerant, ensuring it reaches the evaporator at the correct pressure and temperature.

Cryogenic refrigeration systems play a crucial role in various industries, including medical, aerospace, and food preservation. Understanding the essential components of these systems and their specific functions is vital for effective operation and maintenance. Key components include compressors, condensers, and expansion valves, each contributing to the refrigeration cycle. Compressors increase the pressure of the refrigerant, while condensers facilitate the heat exchange process, converting gas to liquid. Expansion valves control the flow of the refrigerant, ensuring it reaches the evaporator at the correct pressure and temperature.

Tips: Regularly inspecting and servicing these components can prevent potential failures and downtime. Make sure to maintain proper refrigerant levels, as low levels can decrease efficiency and lead to excessive wear on the compressor. Additionally, using high-quality components during maintenance or replacements can enhance the system's overall reliability.

Another integral part of cryogenic systems is the insulation material used to minimize heat transfer. Vacuum insulation systems are especially effective, as they reduce heat flow significantly. When selecting insulation, consider thermal conductivity and durability to ensure optimal performance in extreme conditions.

Tips: Always monitor temperature fluctuations within the system, as these can indicate insulation failure. It's often beneficial to upgrade insulation materials if your system is older, as newer technologies can substantially improve energy efficiency and reduce operational costs.

Efficient cryogenic system design and operation is crucial in the context of modern energy challenges, particularly as we strive for sustainability in various sectors. Recent advancements in liquefied natural gas (LNG) cold energy harnessing present opportunities for reducing energy waste and improving utilization. By applying innovative strategies, engineers can optimize cryogenic systems to ensure they operate at peak efficiency.

**Tip 1:** When designing cryogenic systems, incorporate adaptive AI models. These models enhance the operational algorithms, allowing for precise scheduling and dispatch of energy resources, particularly in urban microgrids where energy demand fluctuates.

Moreover, the integration of sustainable technologies, such as liquid air energy storage systems, underscores the importance of compatibility between cryogenic systems and alternative energy sources. This synergy can facilitate better energy regulation and contribute to the decarbonization of various industries, including shipping and aviation.

**Tip 2:** Adopt a dual-effect thermal energy storage approach, such as a cold/hot Carnot battery system. This not only improves energy efficiency but also helps balance energy supply and demand, making cryogenic refrigeration systems vital players in a sustainable energy landscape.

Cryogenic refrigeration systems play a crucial role in various industries, but they come with their own set of challenges. One common issue is maintaining consistent temperatures, which is essential for processes that require extreme cooling. Fluctuations in temperature can lead to inefficiency or even failure of equipment. To tackle this, operators must implement robust monitoring systems that provide real-time data, allowing for quick adjustments and preventing temperature deviations.

Another significant challenge is the handling of cryogenic fluids, which demand safety protocols and specialized equipment. Leakage or improper handling can result in hazardous situations, including frostbite or explosion risks. To overcome these challenges, training for personnel on best practices and safety measures is vital. Additionally, investing in high-quality storage and transfer systems designed for cryogenic use can minimize risks and ensure safe operations. By addressing these common hurdles, businesses can optimize their cryogenic refrigeration systems, ultimately improving reliability and performance in their critical applications.

| Challenge | Description | Common Solutions |

|---|---|---|

| Insulation Failure | Loss of thermal insulation can lead to energy inefficiency and increased operating costs. | Inspect insulation regularly; use better insulation materials; apply vacuum technology. |

| Leakage | Leaks in the system can cause refrigerant loss and pressure drops. | Routine checks for leaks; use high-quality seals; pressure testing. |

| Component Failure | Components such as compressors and valves may fail due to extreme conditions. | Regular maintenance; invest in durable components; monitor system performance. |

| Control System Issues | Faulty control systems can lead to improper temperature management. | Update software; regular calibration; utilize backup systems. |

| Safety Concerns | Handling cryogenic substances can pose safety risks to operators. | Implement safety training; use protective equipment; strict compliance with safety protocols. |

Maintaining cryogenic refrigeration systems is crucial for ensuring optimal performance and safety in various applications, including medical, aerospace, and industrial sectors. According to the "2022 Cryogenic Systems Market Report," equipment downtime due to improper maintenance can cost companies upwards of $300,000 annually. Regular maintenance schedules that include inspections of insulation integrity, pressure relief valves, and compressor functionality can significantly reduce the likelihood of system failures.

Troubleshooting in cryogenic systems often requires a methodical approach. Data from the "International Journal of Refrigeration" highlights that approximately 20% of system failures are attributed to inadequate refrigerant levels or improper gas mixtures. Technicians should be trained to recognize signs of pressure anomalies, temperature fluctuations, and unusual noises that could indicate underlying issues. Implementing a comprehensive diagnostic checklist can aid in swiftly identifying problems, thereby minimizing wasted resources and enhancing system longevity.