-

Home

-

About us

-

Products

-

Solutions

-

News

-

Blog

-

Contact us

Leave Your Message

Compressed gas is an essential part of various industries and daily life. It refers to gas that has been stored under high pressure. This process allows the gas to occupy a smaller volume, making transportation and usage more efficient. Common examples include gases like oxygen, acetylene, and nitrogen.

Understanding how compressed gas works is crucial. The principles of pressure, temperature, and volume play significant roles. When gas is compressed, it often heats up. This heat can cause safety risks if not managed properly. The need for careful handling cannot be overstated, as improper use leads to accidents.

Despite its benefits, there are challenges. Users must be aware of the potential hazards related to compressed gas. Training and safety protocols are necessary yet often overlooked. This raises questions about responsibility and risk management in the industry. Overall, a deeper understanding of compressed gas can enhance safety and efficiency.

Compressed gas refers to gas that is stored under high pressure. It exists in a container, often leading to a state where the gas is more condensed than its normal atmospheric conditions. The pressure causes the gas molecules to come closer together. This can increase the gas’s utility for various applications.

There are several types of compressed gases. Common examples include oxygen, nitrogen, and carbon dioxide. Each type serves different purposes. For instance, oxygen is vital for medical use. Nitrogen is often employed in food packaging to preserve freshness. These gases can also be dangerous if not handled correctly. Mishandling may lead to explosions or leaks. Inadequate training or equipment can worsen these risks.

Understanding compressed gases requires more than just knowing their types. One must also consider storage methods and safety precautions. Pressure release devices are essential. Still, many overlook basic checks. This neglect can lead to hazardous situations. It’s crucial to prioritize training and awareness in any environment that uses compressed gas.

| Type of Compressed Gas | Common Uses | Hazards | Storage Requirements |

|---|---|---|---|

| Oxygen (O2) | Medical applications, welding | Fire hazard, reactive with flammable substances | Store in well-ventilated areas away from flammable materials |

| Nitrogen (N2) | Inert gas for food packaging, blanketing | Asphyxiation risk in confined spaces | Store in cool, well-ventilated areas |

| Carbon Dioxide (CO2) | Beverage carbonation, fire extinguishers | Asphyxiation in high concentrations | Store in a cool place; avoid direct sunlight |

| Acetylene (C2H2) | Welding and cutting fuel | Highly flammable and explosive | Store in upright position, away from heat |

| Helium (He) | Balloons, cryogenics | Asphyxiation risk in large amounts | Store in a cool and dry environment |

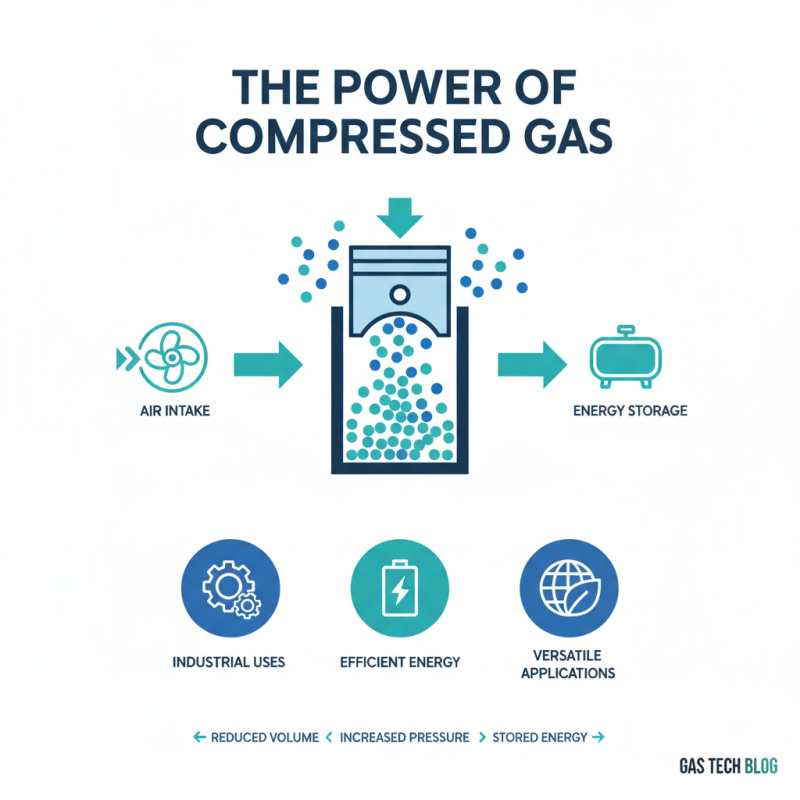

Compressed gas plays a vital role in various industries. The mechanisms behind gas compression are fascinating. Compression involves reducing the volume of gas by increasing pressure. By doing so, gas molecules are forced closer together. This process stores energy efficiently, making it usable when needed.

When gas is compressed, its temperature can rise. This can make managing the system complex. Heat must be dissipated to maintain efficiency. Failing to do so can lead to safety hazards. It's essential to monitor this aspect carefully.

Energy storage using compressed gas has its advantages. It can be stored in tanks or larger systems for later use. However, the infrastructure required is often costly. Maintenance is critical but can be overlooked. Ensuring proper upkeep can significantly enhance performance and safety. Balancing cost and efficiency is a challenge requiring constant reflection.

Compressed gases play a vital role in various industries. They are used for refrigeration, welding, medical applications, and manufacturing. In the food industry, compressed gases help preserve food freshness. For example, nitrogen can create an inert atmosphere, reducing spoilage. This method is commonly used in packaging.

In the manufacturing sector, compressed air is widely utilized. It powers pneumatic tools and machinery, making production more efficient. It drives conveyor belts and operates robotic systems. Moreover, compressed gases find their way into the healthcare field. Oxygen delivery systems and anesthesia machines heavily rely on it.

Despite their significance, there are risks involved. Leaks can occur, leading to dangerous situations. Storage conditions are crucial to prevent accidents. Regular checks and maintenance are necessary to ensure safety. Industries must prioritize effective training for employees handling these gases to mitigate potential dangers. Such measures can enhance operational efficiency and safeguard people.

Handling compressed gas safely requires utmost caution. The National Fire Protection Association (NFPA) states that over 1,400 incidents involving gas cylinders occur annually. These incidents can lead to explosions, fires, and injuries. Proper storage and handling protocols help mitigate these risks. Storing cylinders upright and securing them is essential. This prevents tipping and falling.

When using compressed gases, personal protective equipment (PPE) is crucial. Safety goggles and gloves should always be worn. Ensure proper ventilation in the workspace. Limited air circulation can cause dangerous buildups of gas. The Occupational Safety and Health Administration (OSHA) recommends specific training for personnel. This training includes recognizing hazards and emergency procedures.

In addition to PPE, regular inspection of gas cylinders is necessary. Check for leaks or damage. Remember that improper handling can have serious consequences. A well-structured emergency plan is vital. Each workplace should have procedures to follow in case of an incident. This plan can save lives. Understanding the risks and promoting safe practices can lead to a safer environment.

Compressed gases are widely used in various industries. However, their environmental impact can be significant. When released into the atmosphere, some gases contribute to greenhouse gas emissions. This effect can worsen climate change and harm ecosystems. Regulations are in place to limit these emissions and ensure safe usage.

Tip: Always check local regulations on the handling and storage of compressed gases. Understanding these rules can prevent environmental harm.

Additionally, improper disposal of compressed gas cylinders can lead to hazardous situations. Unused containers can leak and release toxins into the environment. Many areas have specific guidelines for their disposal. Following these can minimize damage to the environment.

Tip: Regularly inspect gas cylinders for leaks and damage. This helps maintain safety and reduce environmental risks. Awareness and adherence to guidelines make a difference. Each small action counts toward sustainability.