-

Home

-

About us

-

Products

-

Solutions

-

News

-

Blog

-

Contact us

Leave Your Message

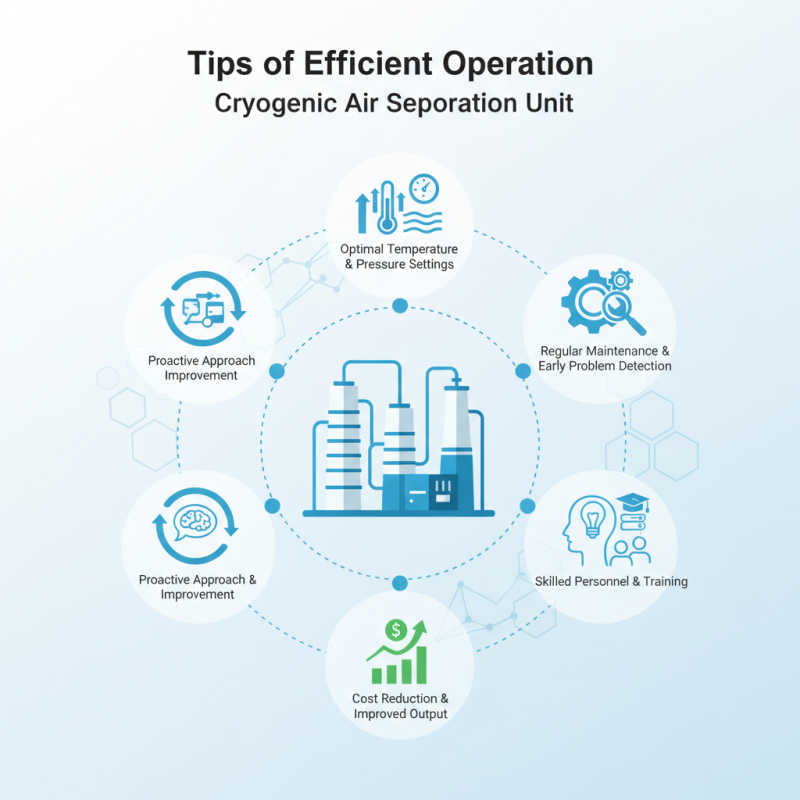

In the realm of industrial gas production, the Cryogenic Air Separation Unit stands out for its efficiency. These units are vital for separating air into its primary components: nitrogen, oxygen, and argon. Optimizing their performance can lead to significant cost reductions and improved output. However, many operators face challenges in achieving peak efficiency due to various factors.

Operating a Cryogenic Air Separation Unit requires attention to detail and understanding of the system’s intricacies. Common issues may arise from temperature fluctuations or pressure disparities. Ensuring optimal settings is crucial for consistent operation. Regular maintenance can be overlooked, leading to inefficiencies. It is essential to identify potential problems early on.

Training personnel is another vital aspect. Skilled operators contribute to better decision-making and problem-solving. Investing time in developing expertise pays off. Ultimately, managing a Cryogenic Air Separation Unit effectively can increase productivity. Reflection on current practices may yield valuable insights into areas for improvement. Embracing a proactive approach will lead to sustainable operations in this field.

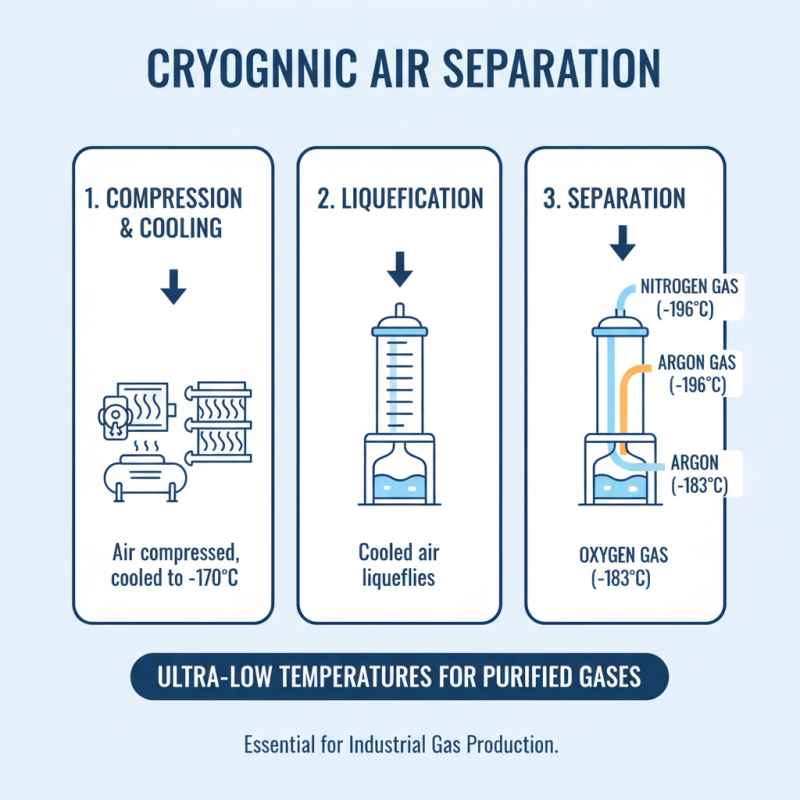

Cryogenic air separation technology is essential for producing gases like oxygen and nitrogen. It operates at incredibly low temperatures. This method effectively separates atmospheric air into its components. Understanding the intricacies of this process is vital for optimizing efficiency.

To ensure efficient operation, proper maintenance is key. Regularly check the heat exchangers for any build-up. Clean them meticulously. This can enhance thermal efficiency significantly. Another tip involves the monitoring of pressure drops. Instabilities can indicate potential issues. Early detection can prevent costly downtimes.

Operators should pay attention to the purity levels of the output products. Sometimes, impurities arise faster than expected. Regular sampling and analysis are crucial. Adjustments might be necessary to keep quality consistent. Efficiency can lead to cost savings, but neglecting these details can cause problems. Engage with your processes and always look for room for improvement.

Cryogenic air separation units (CASUs) play a crucial role in various industries. Understanding their key components is essential for efficient operation. The main components include the air compressor, heat exchangers, distillation columns, and storage tanks. Each part has a specific function, making the unit more effective.

The air compressor pressurizes the ambient air. This step is vital for the separation process. Heat exchangers then cool the air rapidly. The cooling allows for liquefaction, which is pivotal in separating oxygen and nitrogen. The distillation columns do the heavy lifting by separating these gases at various stages. Each column must be calibrated correctly for optimal performance.

Storage tanks hold the separated gases. Ensuring proper insulation and safety protocols is key. Operators often overlook maintenance schedules for these components. This neglect can lead to inefficiencies or even accidents. Regular checks can enhance the lifespan of a CASU. Proper training for staff is also critical. A well-informed team can identify issues quickly.

Optimizing cryogenic air separation units is crucial for better performance. Focus on regular maintenance. It’s essential to check compressors, heat exchangers, and distillation columns frequently. A worn-out component can drastically reduce efficiency. Unexpected downtime can disrupt production schedules.

Monitoring operating parameters is another vital practice. Keep an eye on pressures and temperatures. Slight deviations may indicate underlying issues. An alarm system can be helpful. However, dependency on alarms alone can lead to complacency. Regular manual checks should not be forgotten.

Employee training is paramount. All staff should understand the system mechanics. Misunderstandings can lead to incorrect adjustments. Encourage a culture of communication. Encourage reporting of small anomalies. Often, minor issues can prevent major failures.

This chart illustrates the operational efficiency of a Cryogenic Air Separation Unit (CASU) over a period of six months, measuring the daily oxygen production (in tons) against the electricity consumption (in megawatt-hours).

For efficient operation of Cryogenic Air Separation Units (CASUs), maintenance is key. Regular checks on the cooling system and heat exchangers prevent major failures. Monitoring temperature and pressure helps identify early signs of trouble. Clogged filters can lead to inefficiencies. Cleaning them should not be overlooked.

Visual inspections play a crucial role. Look for signs of wear or leaks in pipes and joints. Small issues may escalate if left unchecked. Maintenance logs can provide insights. Analyzing past problems aids in predicting future ones. Scheduling downtime for maintenance can be challenging. Balancing production with necessary checks requires planning.

Training staff is also essential. Team members need to understand the system's intricacies. An untrained operator might miss crucial details. Regular workshops can enhance their skills. Remember, even small oversights can lead to significant operational setbacks. Continuous reflection on maintenance practices can improve overall efficiency.

Safety is paramount in cryogenic operations. Dealing with extremely low temperatures poses unique risks. Always wear appropriate personal protective equipment (PPE). This includes insulated gloves, full-face shields, and thermal clothing. Accidental exposure to cryogenic fluids can cause severe frostbite. The chilling properties of these substances make it essential to stay alert.

Regular inspections of the equipment are essential. Check for leaks or signs of wear and tear. Even small issues can lead to dangerous situations. Ensure that safety valves and pressure relief systems are functional. Be proactive in identifying potential hazards.

Proper training for all personnel cannot be overlooked. Workers should understand the properties of cryogenic materials. They should be aware of emergency procedures. Nonetheless, there may be gaps in knowledge or complacency. Regular refresher courses will help reinforce safety protocols. Everyone must take responsibility for their safety and that of their colleagues.