-

Home

-

About us

-

Products

-

Solutions

-

News

-

Blog

-

Contact us

Leave Your Message

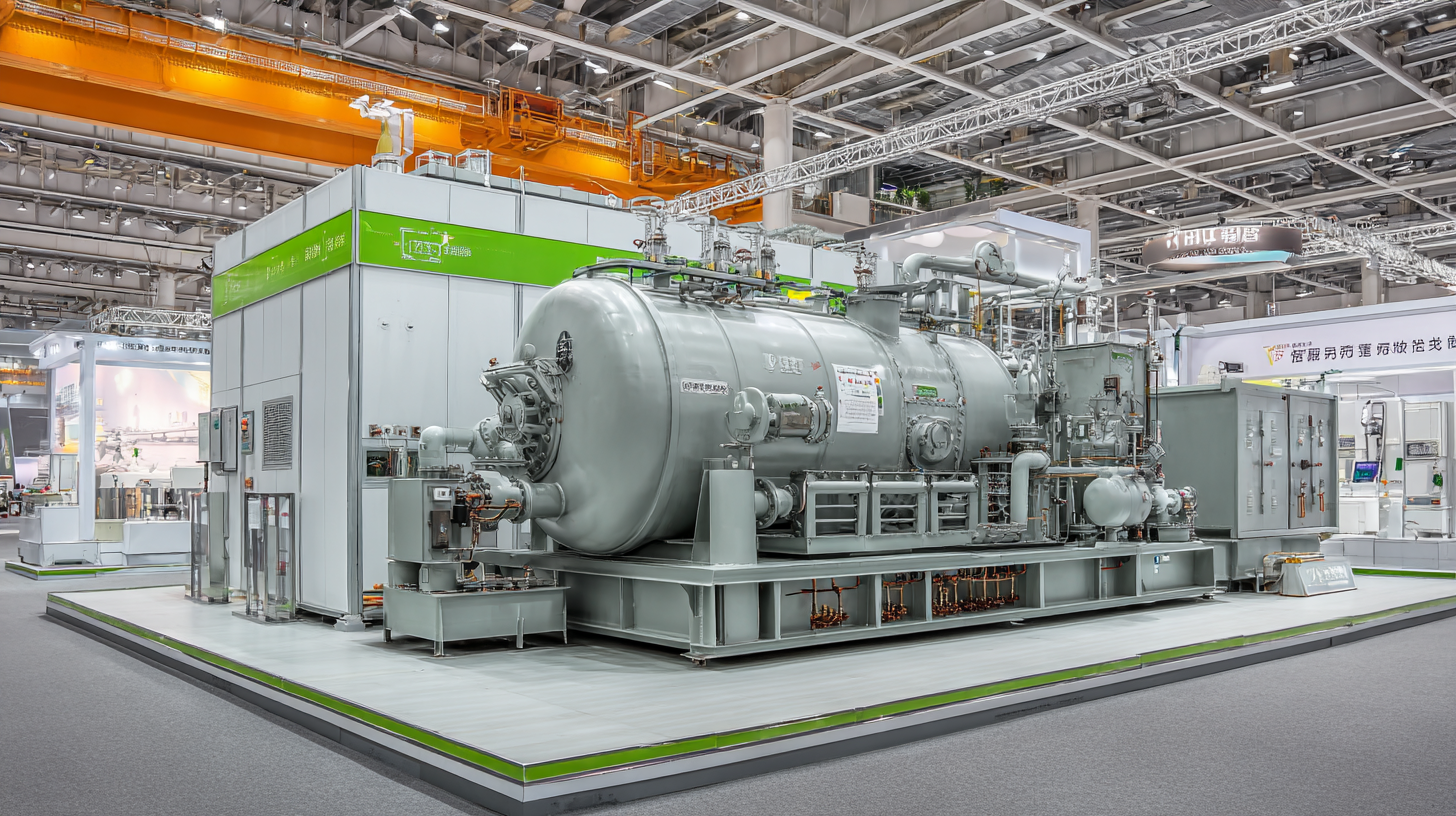

The rapid advancements in Cryogenic Oxygen Plant technology have become a focal point of the global industrial landscape, as evidenced by the recent unveiling of innovative trends at the 2025 China Import and Export Fair. With the global market for cryogenic equipment projected to reach USD 18.5 billion by 2027, reflecting a compound annual growth rate (CAGR) of 5.6%, the significance of cutting-edge solutions in oxygen production is undeniable. Cryogenic Oxygen Plants play a crucial role in industries ranging from healthcare to aerospace, providing essential oxygen with exceptional purity and efficiency. According to a report by ResearchAndMarkets, the increasing demand for liquefied gases and the growing emphasis on cleaner energy sources further bolster investments in this technology. As stakeholders gather at the 138th Canton Fair, the showcasing of these pioneering advancements is not only timely but also indicative of a broader trend towards sustainability and enhanced operational efficacy in the cryogenic sector.

Recent advancements in cryogenic oxygen production techniques were prominently showcased at the 2025 China Import and Export Fair, highlighting innovative methodologies that could significantly enhance operational efficiency. As the global demand for clean and sustainable energy solutions surges—driven by population growth and economic development—the spotlight on cryogenic technologies has intensified. Studies indicate that employing pressure swing adsorption (PSA) for oxygen production can lead to up to 90% energy efficiency in comparison with traditional methods, promising a greener footprint for various industrial applications.

Moreover, the integration of machine learning and computational chemistry in cryogenic systems has the potential to streamline production processes and optimize energy utilization. An industry report suggests that the market for advanced cryogenic technologies is projected to grow at a compound annual growth rate (CAGR) of 7.4% by 2030, emphasizing the urgency for innovative practices to keep pace with evolving energy demands. These developments set the stage for a new era in oxygen production that not only addresses current energy challenges but also aligns with global sustainability goals.

Recent advancements in cryogenic oxygen plant technology are significantly enhancing operational efficiency, as showcased at the 2025 China Import and Export Fair.

The integration of innovative techniques such as pressure swing adsorption (PSA) has been pivotal in transforming how oxygen is produced. PSA technology has evolved with new adsorbents and optimized reactor designs, allowing for higher purity levels and reduced energy consumption. This progress not only lowers operational costs but also meets the increasing demand for oxygen in various industrial applications.

Furthermore, the emergence of advanced carbon capture technologies is complementing these innovations. By employing methods such as ionic liquids and hybrid systems, the efficiency of oxygen plants can be improved while simultaneously addressing environmental concerns. These technologies are especially relevant for different power plant types, suggesting a move towards more sustainable operations. As the industrial gases market is projected to reach USD 126,526.8 million by 2030, the continued development of these cutting-edge technologies indicates a promising future for both cryogenic oxygen plants and the broader industrial sector.

The 2025 China Import and Export Fair showcased groundbreaking advancements in cryogenic oxygen plant technology, particularly emphasizing sustainability practices in the manufacturing process. As environmental concerns continue to rise globally, the cryogenic oxygen industry is adapting by integrating eco-friendly methods into their production systems. This shift not only reduces the carbon footprint but also enhances energy efficiency, making the production of oxygen more sustainable than ever.

The 2025 China Import and Export Fair showcased groundbreaking advancements in cryogenic oxygen plant technology, particularly emphasizing sustainability practices in the manufacturing process. As environmental concerns continue to rise globally, the cryogenic oxygen industry is adapting by integrating eco-friendly methods into their production systems. This shift not only reduces the carbon footprint but also enhances energy efficiency, making the production of oxygen more sustainable than ever.

Tips for manufacturers looking to adopt these sustainable practices include investing in renewable energy sources such as solar or wind to power their facilities. Additionally, implementing advanced recycling systems can help in minimizing waste during the production process. Collaborating with environmental organizations can also provide vital insights and support in developing strategies that align with global sustainability goals.

Another promising trend is the adoption of cutting-edge monitoring technology that allows manufacturers to track emissions and energy consumption in real-time. This data-driven approach enables facilities to identify areas for improvement and optimize their operations for better sustainability outcomes. By prioritizing these practices, the cryogenic oxygen industry can not only meet regulatory standards but also contribute positively to the environment while maintaining high production efficiency.

At the 2025 China Import and Export Fair, the emergence of innovative trends in cryogenic oxygen plant technology highlighted the transformative impact of automation on operations. Automation is reshaping traditional processes within these facilities, enhancing efficiency, and reducing the need for manual intervention. By implementing advanced control systems and artificial intelligence, plant operations can now achieve greater precision in the production and distribution of liquid oxygen, leading to improved safety standards and cost savings.

Moreover, the integration of automation technologies allows for real-time monitoring and data analytics, providing operators with valuable insights into plant performance. This shift not only streamlines operations but also facilitates predictive maintenance, minimizing downtime and extending equipment lifespan. As a result, companies can respond more swiftly to market demands while optimizing resource utilization. The use of automated systems in cryogenic oxygen plants signifies a crucial step toward smarter industrial practices, positioning these facilities for greater competitiveness in the global market.

The 2025 China Import and Export Fair has spotlighted innovative trends in cryogenic oxygen plant technology, showcasing advancements that promise to transform industries. As global trade events serve as a platform for knowledge exchange, they also highlight the future directions of cryogenic oxygen technology. This technology is not only critical in the medical and aerospace sectors but also plays a significant role in energy production and environmental sustainability.

Attendees noted exciting developments such as more efficient gas liquefaction methods and enhanced storage solutions. These innovations could vastly improve operational costs and reduce the carbon footprint of cryogenic plants. Moreover, the integration of digital technologies such as IoT and AI into cryogenic systems allows for better monitoring and management, leading to optimized performance and safety.

**Tips:** When attending trade events, network actively with industry leaders to gain insights into emerging technologies. Consider scheduling meetings with vendors who are leveraging cutting-edge solutions in cryogenic oxygen technology. Staying informed through these interactions can position your organization at the forefront of innovation in this rapidly evolving field.

| Trend | Description | Impact on Technology | Future Directions |

|---|---|---|---|

| Modular Plant Design | Introduction of compact and modular units for flexibility and scalability. | Enhances production capability and reduces installation time. | Adoption in diverse industries such as aerospace and medical. |

| Advanced Cryogenic Liquefaction | Utilization of improved heat exchanger designs for more efficient liquefaction. | Significantly lowers energy consumption and operational costs. | Focus on developing energy-saving technologies and processes. |

| AI and Automation | Integration of AI for operational efficiency and predictive maintenance. | Improves reliability and reduces downtime through proactive measures. | Continued updates to AI models for enhanced decision-making. |

| Sustainable Practices | Adoption of eco-friendly materials and processes in plant operations. | Reduces overall carbon footprint and promotes environmental stewardship. | Enhanced focus on sustainability initiatives in future designs. |